Headphones and earphones

Head- and earphone design from the ground – based on years of experience

Getting the sound you want.

A measured headphone response (magenta curve) compared to the target response (blue curve).

Coupler impedance

IEC 711 coupler

Front leakage with optional acoustic mesh

Driver modelled using TS parameters

Rear leakage with optional acoustic mesh

Air volume behind driver

Internal air volume inside driver

Air volume in front of driver

Optional acoustic mesh on outlet

Very often both 2D and 3D simulations are used to simulate the influence of leakage holes, front- and rear cavities etc.

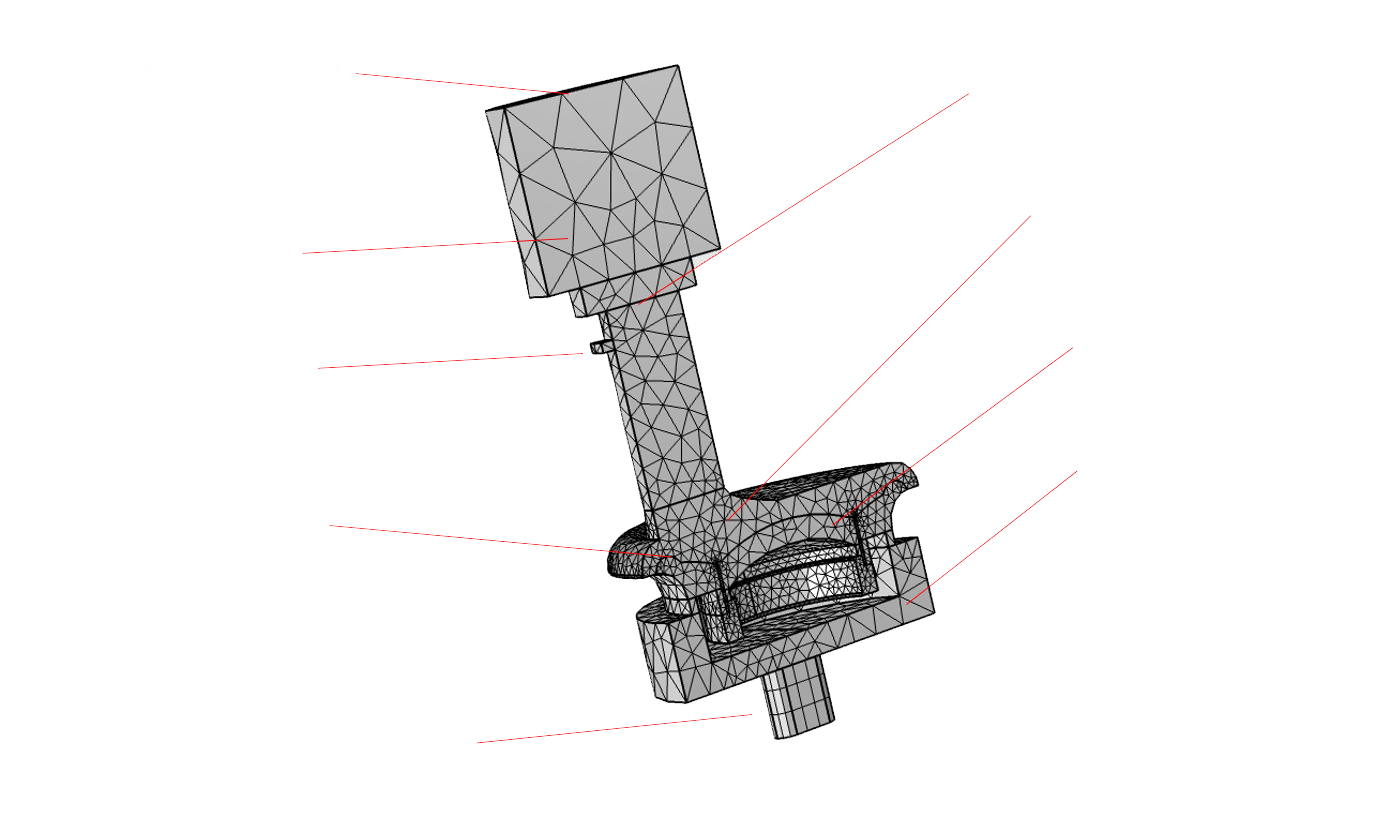

COMSOL Multiphysics® is used to optimize linearity of the compliance and break-up modes. Image shows motion analysis performed on a diaphragm for a 50mm receiver.

Drilling holes, modifying front-to-back leakage, changing mesh densities…

The above mentioned simulation tools helps us in giving the customer a very short delivery time for actual having the prototypes in hand for initial listening tests and also laboratory tests for documentation.

Normally “soft Tooling” parts will be made based on these simulation results using 3D printing. Laser Cutting, CNC processing, etc. leading to hand assembled prototypes ready for sharing with our customers for their evaluation.

Using standardized test methods